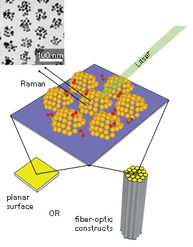

Since its first observance Surface-enhanced Raman scattering (SERS) has shown potential for detection of cancerous tumors, food pathogens and bio-security threats. However, with having to meet ever-increasing commercialisation demands – SERS sensitivity and how the signals from molecules of the aforementioned agents require greater enhancement or bio-sensitivity has led to the current stalemate in SERS R&D optimisation endeavors. Recently an A*STAR research team have fabricated a remarkable regular array of closely packed Gold nanoparticle (AuNP) clusters that it is claimed will improve SERS sensor sensitivity.

The principle bio-chemistry of Raman scattering arises when molecules scatter at wavelengths not present in the light inducement source. Typically such molecules can be detected with SERS sensors by bringing them into close contact with a nano-structured metallic surface, which subsequently illuminates by a laser inducement reaction at a particular wavelength. An ideal SERS sensor should have the following characteristics:-

- Dense but homogeneous packing of metallic nano-structures to produce repeatable signal feedback levels

- The surface sensor nanomaterial typically being either Gold (Au) and Silver (Ag), which will enable the intensifying of the resultant Raman scattering

- Ideally an economical construction

- High-degree of robustness to sustain sensing performance over time

Unfortunately, few of the many existing approaches succeed in above categories. However, it is claimed Fung Ling Yap and Sivashankar Krishnamoorthy at the A*STAR Institute of Materials Research and Engineering (IMRE) have managed to produce closely packed nano-cluster arrays of Au that incorporate the most sought-after features for nano-fabrication and sensing. In addition, to flat base substrate surfaces, they also succeeded in coating fiber-optic tips, which has been speculated as being promising for the development of remote-sensing applications. Due to the nano-fabrication methodology derived and how it is entirely chemically ‘self-assembled’ – it is claimed that the method does not require specialist equipment or the utilisation of a clean-room facility, so highly applicable for low-cost commercialisation implementation. Original article available here

DCN Corp also believes it has developed a coating methodology which succeeds in some or all of the above-mentioned metallic SERS sensor characteristics. Therefore, if you believe you or your colleagues are interested in making the above a reality – please ensure to contact the company as soon as practicably possible.