Low-level concentration of organic contaminants in air and drinking water is a key sensor industry. Recent research published at University of Notre Dame (UoND) by the laboratory of Professors Prashant V. Kamat and John A. Zahm could provide a beneficial detection mode to these contaminants.

Interestingly Kamat’s laboratory smartly utilised the benefits gained from Surface-enhanced Raman spectroscopy (SERS) by using Silver nanoparticles (AgNP) to increase the sensitivity limit of chemical detection. The researchers have synthesised a semiconductor-Graphene-metal thin film that could have distinct advantages. Such advantages could be the absorption of organic molecules on the film’s Graphene surface, which subsequently increases the local contaminant adjacent to AgNPs. Strategically the researchers investigated the use of Graphene oxide films, whereby on the opposite sides of the Graphene surface Titanium dioxide (TiO2) and metallic nanoparticles were deposited. Kamat continued to claim that “we are currently working towards the detection of environmental contaminants at even lower-levels”. In addition, Kamat stated “careful control of metal size and loading will be the key to optimise strips for testing water quality”

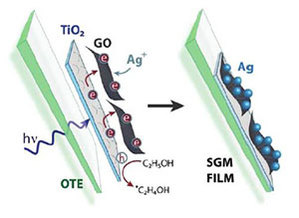

As highlighted in the schematic (above) the superior conducting properties of Graphene sheets are well known when deposited on various base substrate topologies, but the Kamat group demonstrated that the transport of electrons is not limited in a 2-D plane. Proactively a ‘hoping’ of electrons was found for via one side of the Graphene base substrate, which enables for side-selective deposition of AgNPs. The research was published in the Journal of Physical Chemistry Letters – in a paper entitled “Electron Hopping Through Single-to-Few-Layer Graphene Oxide Films: Side-Selective Photocatalytic Deposition of Metal Nanoparticles”. Original article available here

DCN Corp believes it has also devised a novel but more so an universal nano dip coating methodology, which could provide a systematic understanding of controllable metallic particle sizes and its subsequent loading. Therefore, if you believe you or your colleagues are interested in making the above a reality – please ensure to contact the company as soon as practicably possible.